Context

As space is important for Europe, the European Commission has created a specific line in the Leadership in Enabling and Industrial Technologies Programme in order to boost innovation and create new sources of jobs and growth. This year, in the ‘Earth Observation’ section of the Work Programme the LC-SPACE-14-TEC-2018-2019 topic specifically targets the maturation of application-oriented technologies, with a subtopic dedicated to Very high resolution optical EO for LEO and/or high resolution optical EO for GEO/HEO instrument technologies.

Video mission for Earth Observation will be the next step of optical instrument goals. It will allows to answer to new types of problematic and missions, specifically associated with on board Artificial Intelligence, as it opens the possibility to process a wide amount of data on board.

Presently, due to technological limitation on data processing and downlink data rate, there is no instrument on the market designed to collect big amount of data.

The VIDEO project will be a new type of instrument designed to be used with next generation of Artificial Intelligence processing capacity on board. It will allow Europe to takes the lead on the EO market within the next years.

Due to its specific and innovative technologies and architecture adapted to new generation of data processing, the VIDEO instrument will be the pathfinder of the next instrument generation for Earth Observation.

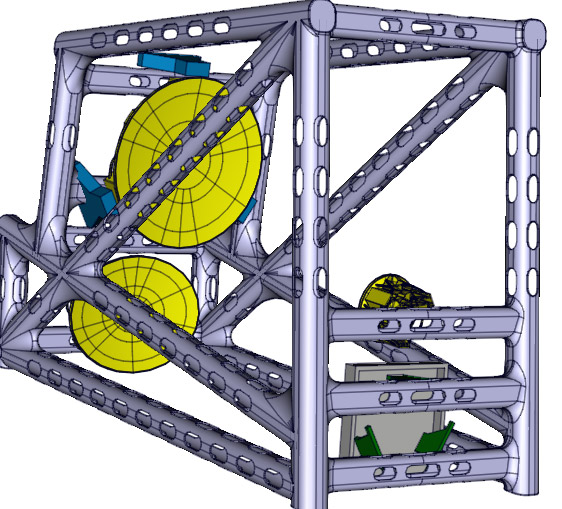

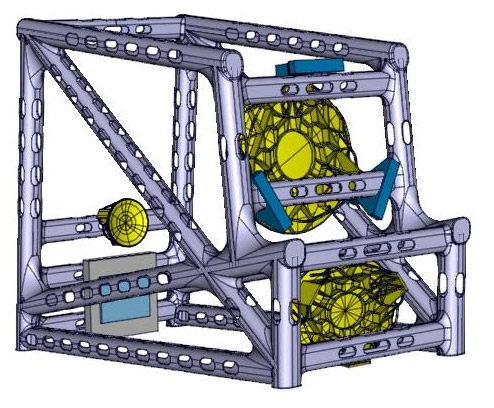

Figure 1: VIDEO instrument preliminary architecture (front and rear view)

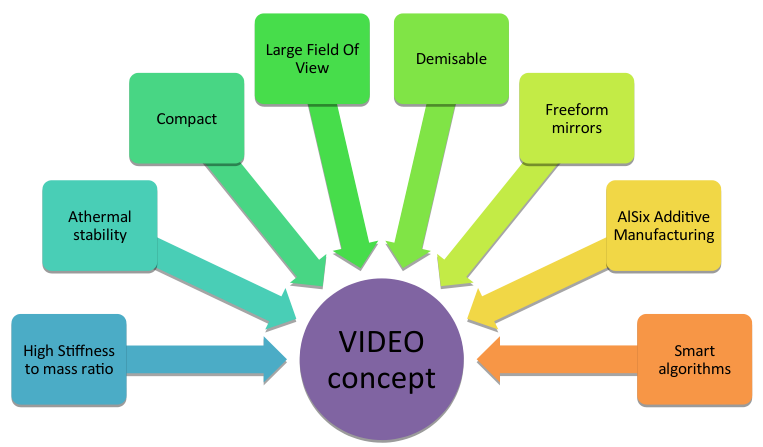

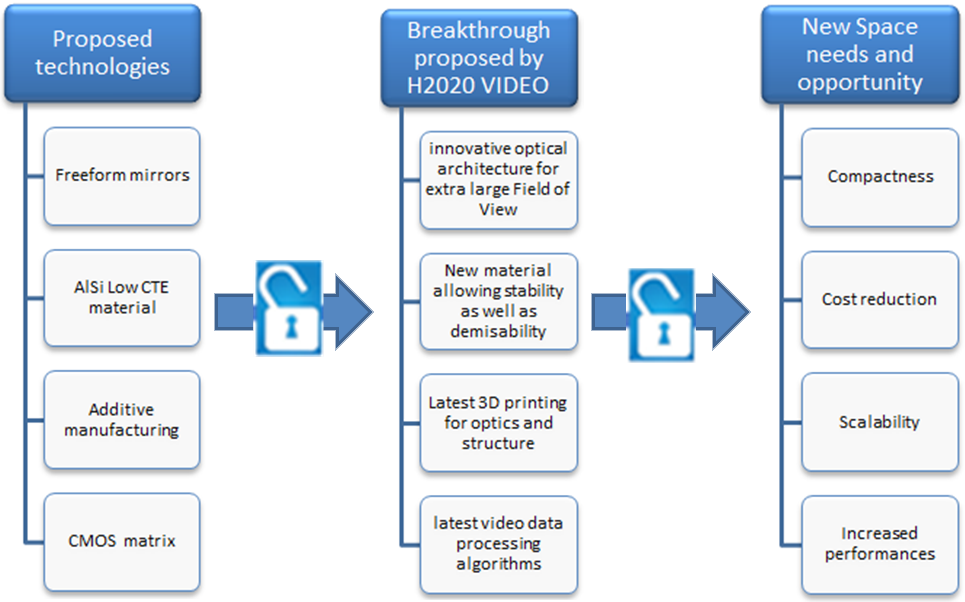

The VIDEO project proposes a set of breakthrough technologies for instruments for Earth Observation. Indeed, the VIDEO project is the future of the small and compact instrument with extra wide field of view. Based on TAS’ exclusive patent combining freeform mirrors in a smart optical compact combination and latest advances in material development, the VIDEO instrument will have the capability to perform High Resolution images as well as video monitoring on an extremely wide scene.

The Field of View for this type of imager instruments (based on 3 FF mirrors) will be about 10 times higher in surface than the equivalent instrument volume without freeform disruptive solution.

On top of that, the idea of the VIDEO project instrument is to combine the latest technologies in terms of Additive Manufacturing for low Coefficient of Thermal Expansion (CTE) AlSix material development, in order to have same material for structure and mirrors. AlSix is a material specifically developed in order to adapt its CTE to the desired value thanks to the proportion of Si added in the Aluminum matrix (“x” refers to the proportion of Si in the material). Thanks to that, the instrument will have an extremely stable and homothetic behavior for optical point of view, as well as an optimized stiffness to mass ratio.

And last but not least, due to the AlSix based material for mirrors and structure, the instrument will be one of the best in class in terms of demisability (due to AlSix low melting point and additive manufacturing light weighted structure) compared to similar concept in ceramic solutions; and, in the perspective of being parts of future small satellite observation constellations, it will be a strong argument.

Figure 2: VIDEO instrument advantages

The consortium includes 6 entities from 3 different European countries, combining the skills of academics and SMEs, and three large industrial companies, among which the project coordinator, Thales Alenia Space, is a Large system integrator for spacecraft, renowned for its specialty in optical observation instruments. The VIDEO project will includes the latest advances in Europe technologies for telescope structure and mirrors as well as latest innovative solution for video detection, acquisition, treatment and compression.

As the final purpose of the VIDEO instrument is to demonstrate video monitoring on a wide scene with autonomous motion detection and ranging capacity, the project will include video channel development in order to integrate latest CMOS matrix technologies as well a smart algorithm. An end to end ground demonstration with a downscaled demonstrator instrument will be performed in the frame of the project to prove the capacity of the overall European supply chain to Produce, Assemble, and Test the VIDEO instrument by using the best skills in Europe in all these domains.

Figure 3: VIDEO instrument breakthrough concept