Freefrom Metallic Mirrors in AlSix technology

Freeform mirror technology allows to increase the capability to propose compact optical instruments for Earth observation with a very large field of view, which is not possible with the classic mirror technology. It allows to design optical combination with wide field of view without downgrading performances on the useful field of view.

Among the currently available solutions combining new materials with new concepts of mirror structure and shape, the AlSix material is most likely the most promising one, as it allows to perform additive material structure for optimized mass and light weighting, and diamond manufacturing for freeform shaping. In the case of mirrors, up to now Europe mainly concentrated its developments on monolithic ceramic (Silicon Carbide and Silicon Nitride) and glass-ceramic (Zerodur®) substrates because of a choice to favor the stability properties. But these solutions are reaching a limit of light-weighting (for Zerodur®) and polishing duration (for Ceramics), especially for small size mirror due to the hardness and/or fragility of the material. The VIDEO project proposes a different choice: the AlSix material combined with additive manufacturing technology is optimum to guarantee the advantage of ceramics for light weighted properties (due to additive manufacturing capability) and the advantage of metallic parts for machining and polishing, the only drawback could the thermal stability, that’s why today, it only answers to small mirrors manufacturing which are less sensitive to thermal gradients and deformations on optical performances.

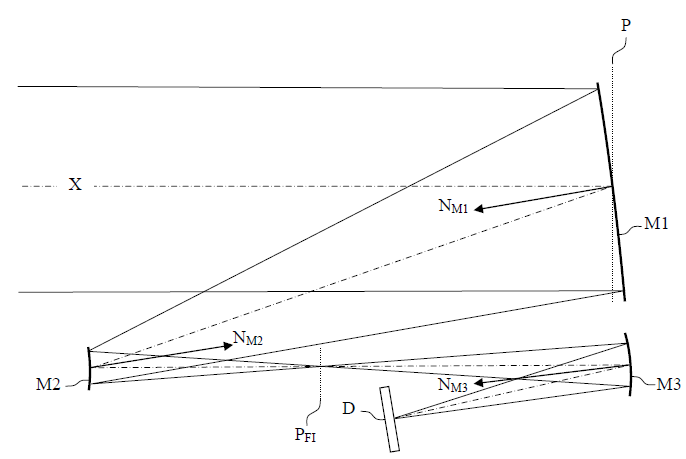

Figure 4: TAS exclusive combination with freeform mirrors.

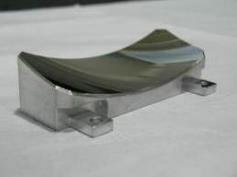

Figure 5: Metallic Mirror freeform example

In order to reach the objectives of the targeted markets, the Telescopes have to use freeform mirror technology with the following design drivers:

- Very high stiffness-to-mass ratio, in order to have sufficiently light mirrors.

- Efficient polishability for both time optimization and adaptation to required performance.

- Optical quality of the mirror (polishing to very low roughness, with uniform behaviour all over the optical face)

- Scalability