AlSix additive manufacturing

Additive Manufacturing is an emerging family of technologies that build functional parts directly from 3D CAD files. Applications using these technologies encompass a variety of industries including automotive, medical, military, and other industries that require complex parts of small to medium size and in small batch quantities.

The expansion of Additive Manufacturing to include metallic materials is a relatively recent development, thus only a short list of material powders are currently available for processing. This new material AlSix is an important step in the continued development of this technology. Today, there is no aluminum alloy with a low CTE available for Additive Manufacturing processing.

Materials with a low CTE are of special interest in space applications due to the requirement of high dimensional stability under temperature change. High thermal conductivity and low material density are also relevant properties and satellites present an opportunity where many components require all of these properties.

These satellites use more and more carbon or ceramic based structures with CTE close to zero. Thus, the need for compatible low CTE materials increases and the complexity of parts that can be produced by Additive Manufacturing is attractive for both competitiveness and performance; especially considering weight objectives.

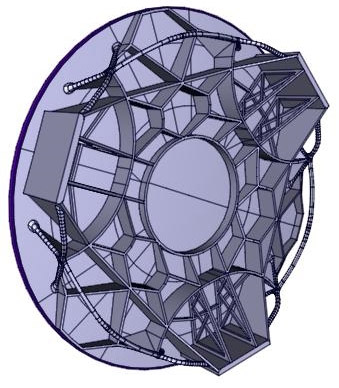

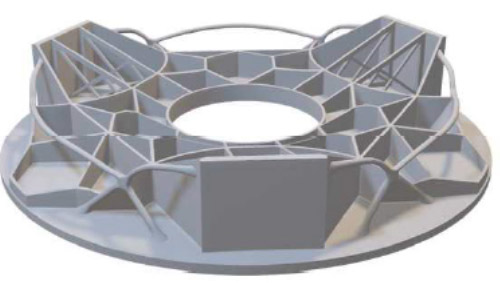

The VIDEO project will Demonstrate that AlSix material coupled with additive manufacturing technologies is a relevant approach regarding space optical structure.

↓

Figure 6: Example of Mirror design in additive manufacturing (from CAD to real part)